Home

> Products > Motion Control > Motorized Stages > Motorized Vertical-Motion Stages>

CZF series high Precision Motorized Vertical-Motion Stages

.jpg)

.jpg)

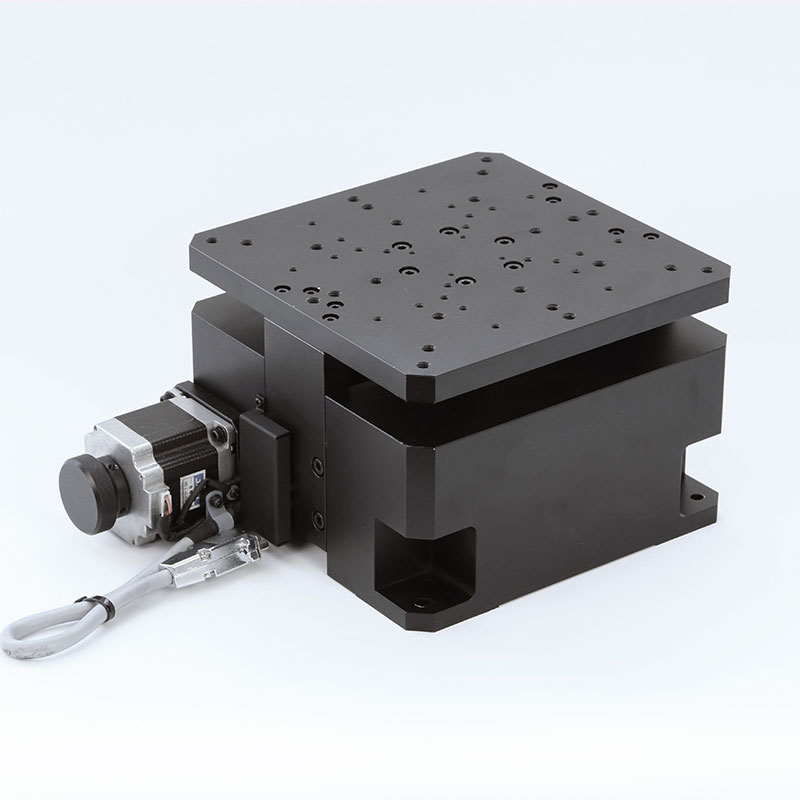

CZF series high Precision Motorized Vertical-Motion Stages

CZF series products are precise motorized vertical-motion stages designed and manufactured by Zolix to meet the requirements of applications with high-precision and high repeated operation rate.

Features:

See All FeaturesShow Filters:

Description:

CZF series products are precise, motorized vertical-motion stages designed and manufactured by Zolix to meet the requirements of applications demanding high precision and high repeatability. The main body materials are hard, black anodized aluminum alloys, ensuring greater durability and offering an attractive appearance. This series of stages delivers higher motion precision, benefiting from the use of linear-slider (or cross-roller) guides, which feature high strength, a high load capacity, and excellent durability. These products are ideal for integration into automation equipment or instruments with strict requirements regarding space, size, and weight. They are also well-suited for use on production lines with short travel ranges requiring high repetition rates.

CZF series products are precise, motorized vertical-motion stages designed and manufactured by Zolix to meet the requirements of applications demanding high precision and high repeatability. The main body materials are hard, black anodized aluminum alloys, ensuring greater durability and offering an attractive appearance. This series of stages delivers higher motion precision, benefiting from the use of linear-slider (or cross-roller) guides, which feature high strength, a high load capacity, and excellent durability. These products are ideal for integration into automation equipment or instruments with strict requirements regarding space, size, and weight. They are also well-suited for use on production lines with short travel ranges requiring high repetition rates.

Features:

• Ball screws with high-quality stepping motors provide higher resolution and positioning accuracy.

• Linear-slider or cross-roller bearing guides offer high strength, heavy load capacity, and excellent durability.

• Fine-grinding techniques are applied to the installation surface of the guides to ensure high motion accuracy.

• Three sensors (two for position limits and one for the origin point) operate with highly flexible cables. Modular cable units make maintenance easier.

• Ball screws with high-quality stepping motors provide higher resolution and positioning accuracy.

• Linear-slider or cross-roller bearing guides offer high strength, heavy load capacity, and excellent durability.

• Fine-grinding techniques are applied to the installation surface of the guides to ensure high motion accuracy.

• Three sensors (two for position limits and one for the origin point) operate with highly flexible cables. Modular cable units make maintenance easier.

Naming rules:

| Model | CZF8-60** | CZF20-120 | CZF40-200 | |

| Mechanical specifications | Travel range(mm) | 8 | 20 | 40 |

| Stage surface size(mm) | 60×60 | 120×120 | 200×200 | |

| Ball screws | φ6, 1mm lead | φ12, 5mm lead | φ16, 10mm lead | |

| Transmission mechanism | Timing belt | worm gear and worm | worm gear and worm | |

| Transmission ratio | 1:1 | 80:1 | 120:1 | |

| Travel range with one rotationof motor(mm) | 1 | 0.0625 | ≈0.083 | |

| Material of worm gear | / | Wear-resistant tin bronze | Wear-resistant tin bronze | |

| Material and processtechnology of worm | / | Steel, high frequency quenchinged | Steel, high frequency quenchinged | |

| Guide | crossed-roller bearing guides | linear-slider guides | linear-slider guides | |

| Main body material andsurface | Black anodized aluminum alloy | Black anodized aluminum alloy | Black anodized aluminum alloy | |

| Shaft coupling | / | 19/5/5 | 30-6.35-6.35 | |

| Weight(Kg) | 1 | 4.2 | 12.5 | |

| Accuracy specifications | Resolution (step/half-step)(µm) | 5/2.5 | ≈0.31/0.155 | ≈0.42/0.21 |

| 8-fine-subdivision resolution(µm) | 0.625 | ≈0.039 | ≈0.052 | |

| Max speed(mm/s)* | 5 | 0.625 | 0.833 | |

| Repositioning accuracy (um) | ≤±3 | ≤±2 | ||

| Zero-load Backlash(um) | / | ≤15 | ≤15 | |

| Static parallelism (mm) | ≤0.1 | ≤0.1 | ≤0.12 | |

| Electrical specifications | Motor and its stepping angle(°) | Two phase 28 stepping motor,1.8 | Two phase 42 stepping motor,1.8 | Two phase 57 stepping motor,1.8 |

| Brand and model number ofmotor | Shinano,STP-28D1003-1504 | Shinano,SST43D2126-10 | Shinano,SST59D3206 | |

| Working current(A) | 1.5 | 1.7 | 2.8 | |

| Motor torque(N-m) | 0.0785 | 0.456 | 1.44 | |

| Brand and model of steepingdriver | Moons, SR2 | Moons, SR2 | Moons, SR4 | |

| Type of plug for stage | DB9(pin) | DB9(pin) | DB9(pin) | |

| Type of cable for stage | High flexibility cable (Helukabel, Germany) | High flexibility cable (Helukabel, Germany) | High flexibility cable (Helukabel, Germany) | |

| Length of connectioncable(m) | 0.2 | 0.2 | 0.2 | |

| Position-limit sensors (built-in) | 2*GP1S09xHCPI(JAPAN SHARP) | 2*GP1S09xHCPI(JAPAN SHARP) | 2*GP1S09xHCPI(JAPAN SHARP) | |

| Origin-point sensors (built-in) | 1* GP1S09xHCPI(JAPAN SHARP) | 1* GP1S09xHCPI(JAPAN SHARP) | 1* GP1S09xHCPI(JAPAN SHARP) | |

| Voltage of power supply forsensors (V) | DC5~24V±10% | DC5~24V±10% | DC5~24V±10% | |

| Current consumption(mA) | <60 (total) | <60 (total) | <60 (total) | |

| Sensor Control output | NPN open collector output DC5~24V 8mA or lessResidual voltage 0.3V or less (when load current is 2mA) | NPN open collector output DC5~24V 8mA or lessResidual voltage 0.3V or less (when load current is 2mA) | NPN open collector output DC5~24V 8mA or lessResidual voltage 0.3V or less (when load current is 2mA) | |

| Status of output ports | Output ON when sensor is blocked | Output ON when sensor is blocked | Output ON when sensor is blocked | |

| Maximum loadcapacity | Horizontal direction(Kg) | 4 | 20 | 30 |

| *Note: Highest speed is measured under zero-load conditions with the motor running at 600 RPM. **Note: No self-locking function after power off. |

||||

Filter:

Request for Information

Do you have any questions or requests? Use this form to contact our specialists.