Home

> Products > Motion Control > Motorized Stages > Motorized Vertical-Motion Stages>

PSAV Series Long Travel Range Motorized Vertical-Motion Stages

PSAV Series Long Travel Range Motorized Vertical-Motion Stages

PSAV series motorized vertical-motion stages employ ball screw reducers to ensure ultra-high loading capability. High load capacity, long stroke type.

Features:

See All FeaturesShow Filters:

Description:

PSAV series motorized vertical-motion stages employ ball screw reducers to ensure ultra-high loading capability. The backlash clearance of ball screws reducers is much smaller than that of trapezoidal reducers and it is helpful to provide higher motion accuracy and positioning accuracy. The smooth running is guaranteed by using selected aluminum alloy and four pieces of linear bearing guides. A wider travel range of 50-400mm is offered by this series products which can meet most of customers' requirements. This is a series of motorized verticalmotion stages to be suitable for the applications which need higher loading capability and longer travel range in optical experiments, fine positioning and fine processing.

Main characteristics:

•Longer travel range and higher loading capability are guaranteed by using ball screw reducers

•Four pieces of linear bearing guides constitute guiding mechanism to ensure high motion accuracy and smooth running

•Long travel range is up to 400mm

•Reliable standard two-phase 57 stepping motors have characteristics of high torque and high loading capability

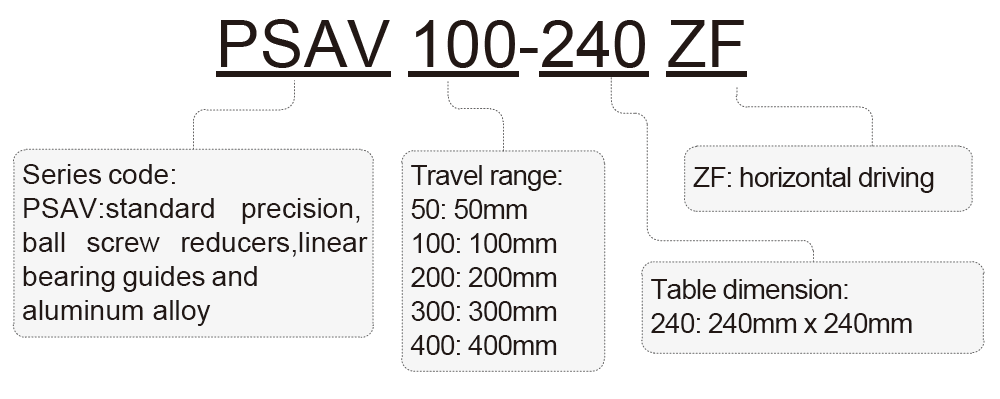

Naming rules:

| Model | PSAV50-240ZF | PSAV100-240ZF | PSAV200-240ZF | PSAV300-240ZF | PSAV400-240ZF | |

| Mechanical specifications | Travel range(mm) | 50 | 100 | 200 | 300 | 400 |

| Stage surface size(mm) | 240×240 | 240×240 | 240×240 | 240×240 | 240×240 | |

| Transmission mechanism | φ40×5 Ball screws reducer,reduction ratio is 4:1 | φ40×5 Ball screws reducer,reduction ratio is 4:1 | φ40×5 Ball screws reducer,reduction ratio is 4:1 | φ40×5 Ball screws reducer,reduction ratio is 4:1 | φ40×5 Ball screws reducer,reduction ratio is 4:1 | |

| Guide mechanism | 4* linear-bearing guides | 4* linear-bearing guides | 4* linear-bearing guides | 4* linear-bearing guides | 4* linear-bearing guides | |

| Main body material and surface | Black anodized aluminum alloy | Black anodized aluminum alloy | Black anodized aluminum alloy | Black anodized aluminum alloy | Black anodized aluminum alloy | |

| Weight(Kg) | 14 | 16 | 20 | 24 | 28 | |

| Accuracy specifications | Resolution (step/half-step) (µm) | 6.25/3.125 | 6.25/3.125 | 6.25/3.125 | 6.25/3.125 | 6.25/3.125 |

| 8-fine-subdivisionresolution(µm) | 0.781 | 0.781 | 0.781 | 0.781 | 0.781 | |

| Max speed(mm/s)* | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | |

| Electrical specifications | Motor and its stepping angle(°) | Two-phase 57 stepping motor, 1.8 | Two-phase 57 stepping motor, 1.8 | Two-phase 57 stepping motor, 1.8 | Two-phase 57 stepping motor, 1.8 | Two-phase 57 stepping motor, 1.8 |

| Model number of motor** | MS-57BYG250CSC | MS-57BYG250CSC | MS-57BYG250CSC | MS-57BYG250CSC | MS-57BYG250CSC | |

| Working current(A) | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | |

| Holding torque of motor(mN·m) | 1900 | 1900 | 1900 | 1900 | 1900 | |

| Brand and model number ofstepping driver (optional) | Moons, SR4 | Moons, SR4 | Moons, SR4 | Moons, SR4 | Moons, SR4 | |

| Type of plug for stage | DB9(pin) | DB9(pin) | DB9(pin) | DB9(pin) | DB9(pin) | |

| Position-limit sensors (built-in) | 2*KX-SS-5GL2 | 2*KX-SS-5GL2 | 2*KX-SS-5GL2 | 2*KX-SS-5GL2 | 2*KX-SS-5GL2 | |

| Voltage of power supply forsensors (V) | DC5~24V±10% | DC5~24V±10% | DC5~24V±10% | DC5~24V±10% | DC5~24V±10% | |

| Control output | Dry contact point output | Dry contact point output | Dry contact point output | Dry contact point output | Dry contact point output | |

| Status of output ports | Output ON when sensor is triggered | Output ON when sensor is triggered | Output ON when sensor is triggered | Output ON when sensor is triggered | Output ON when sensor is triggered | |

| Maximum loadcapacity | Horizontal load(Kg)*** | 200 | 180 | 150 | 120 | 100 |

|

*Note:Highest speed is measured with the conditions of zero-load and motors being worked at 600rpm |

||||||

Filter:

Request for Information

Do you have any questions or requests? Use this form to contact our specialists.